CETUS3D Z BANDING HOW TO

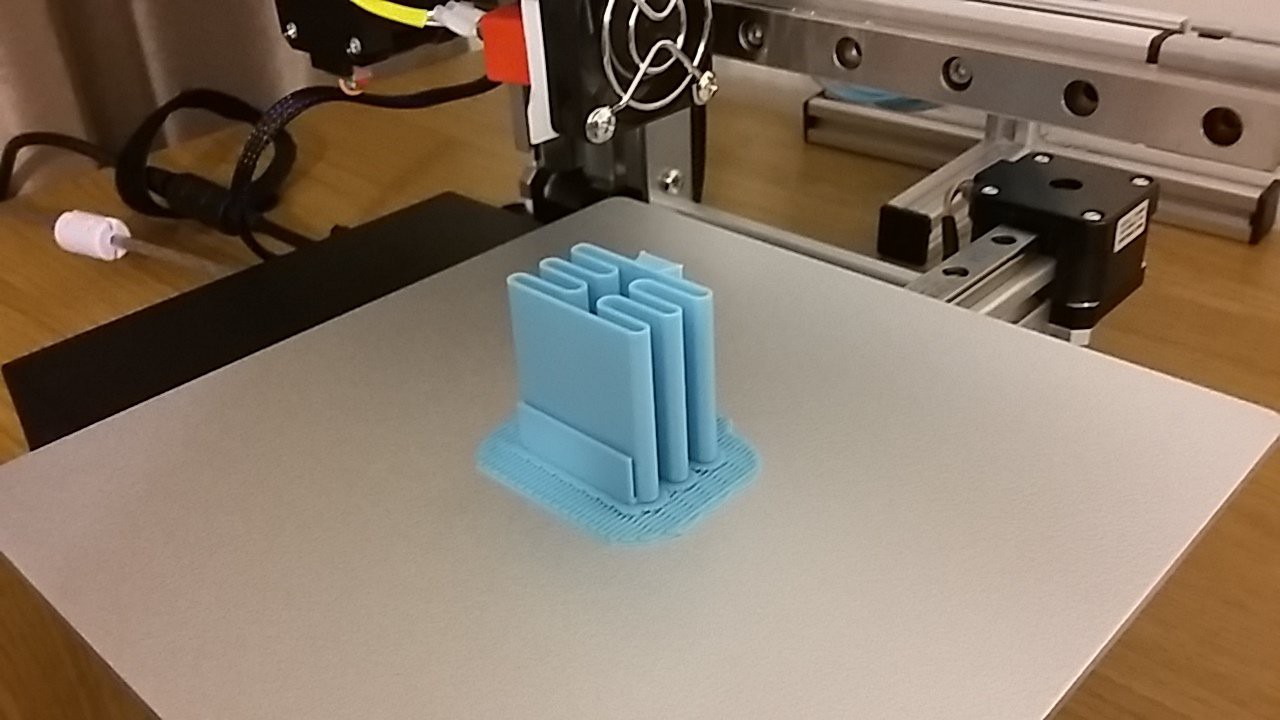

I’ll explain the most common causes and then go over how to resolve them. There are a lot of reasons Z banding could occur. Causes Of Z Banding In 3D Printers And How Fix It Z banding results in a ribbed surface instead of a flat one. Sometimes, Z banding looks like a bulge around the part in only a few layers, with the rest of the model looking normal. Z banding is usually the appearance of a uniform pattern in print layers that stick out from the part. Z banding looks like lines or ribs on a print where it should be smooth. Loose screws are also a common cause of defects like Z banding. This is caused mostly by lead screws or motor shafts that are bent. Z banding occurs when the printer doesn’t move straight up and down the Z axis during a print. It’s a print defect found in FDM printers caused by multiple factors which I’ll cover shortly. Z banding makes it impossible to print parts with a smooth finish.

So the part ends up with obvious layer lines that ruin the appearance of the print. It is hard to mount the rods perfectly with the couplers, a little misalignment and one introduces wobble (X/Y wiggle).Īnyway, M6 gives slightly higher resolution in Z axis with 0.005mm per motor step.Z Banding in 3D printing is a defect in the Z axis that causes print layers to protrude from the part. wobble seems mostly introduced by the couplers (either printed or PVC pipe):.less wobble, but still wobble despite of “straight” M6 threaded rods.

CETUS3D Z BANDING PRO

I made a small package Geeetech / CTC DIY I3 Pro B M6 Z Axis Conversion to use M6 threaded rods instead of M8. Recommendation: print the mounts, print the two bearings, and print the XYZ Calibration Cube or whatever reference item, and see yourself which option works better for you. What I noticed was, once I used the printable bearings for a print, and removed it, the threaded rods wobble already less – but as said, best results I achieved with no bearing and wide floating ends or with the tight bearings. whether left and right go the same way or cancel each other wobble out. I would also guess, the unevenness of the threaded rods and their position to each other also matters, e.g. 1-2mm play.īest results I achieved with floating ends or with tight bearing – in other words, either leave it open or make it stay close, but worst is to give it a little play and threaded rods will show their unevenness on the prints. Worst Z wobble was with original Z mount with ~4mm play or the loose bearing with apprx. You may print two bearings (OD 22mm, ID 8mm), make sure to test inner diameter, so the threaded rod slides smoothly – if required use a 8mm drill to widen the inner hole. The new Z bracket provides more space for the threaded M8 rods than the original wooden bracket: The issue isn’t simple: with or without fixation gives good results, some fixation gives more bad print results. Giving it some space on the top means the inherent wobble of the rod is distributed between top and X gantry – giving wobble artifacts on the print. Which means, either give it a lot of space so the upper end of the Z threaded rods can float, and thereby the X gantry can stay fixed (and not wobble) – or – fix the threaded rods and suppress wobble (there is still wobble but restricted). original bracket: worst wobble of all, Z edge wobbly.loose bearings: noticeable artifacts / wobble, Z edge wobbly.tight bearings: gives very good surface, slightly worse than with no bearings.no bearings / open floating: gives the smoothest surface, most straight Z edge.Now comes the surprise, the best surface (best to worst): new Z bracket with printed bearings (tight tolerance).new Z bracket with printed bearings (with loose tolerance).new Z bracket without printed bearing, apprx.New Z bracket mounts (black), without/with printed bearing (white): printable bearing added to restrict end (optional).bearing hole widened to have more floating.changed structural holes (larger hole -> smaller holes).I hesitated to use lead screws due decrease of resolution (M8: 1 cycle = 1.25mm height, lead screw like TR8x8 (8mm dia, 4 starts, 2mm pitch, 8mm lead => 1 cycle = 8mm height) but otherwise gaining pretty straight lead.Īnyway, I searched Thingiverse for Z mounts for the CTC DIY and found a few, and adapted one design and made a remix Geeetech / CTC Prusa i3 DIY – Z Axis Bracket Remix with printable Bearing :

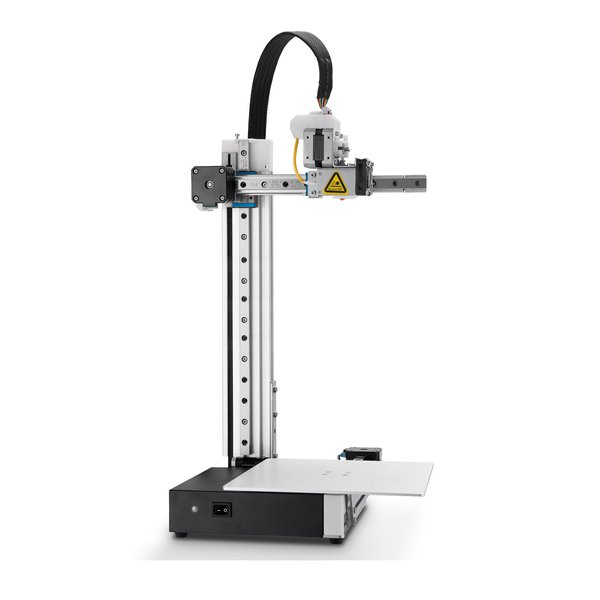

Using a low-cost 3D printer like CTC DIY I3 Pro B (Geeetech I3 Pro B clone) with M8 threaded rods as Z axis with loose or floating ends is what you get – and so also some wobble or banding on the X axis due slightly bent M8 threaded rods – they barely come straight.

0 kommentar(er)

0 kommentar(er)